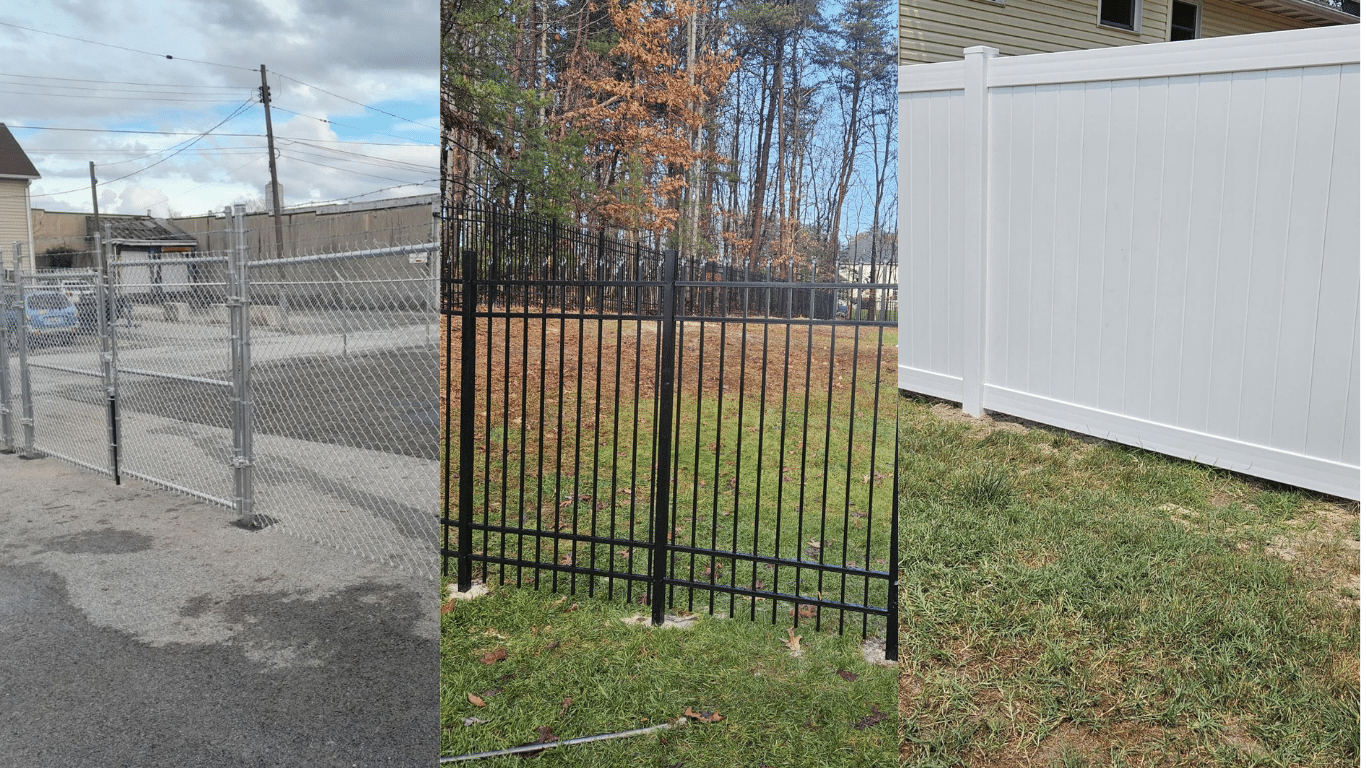

Fences face blazing sun, sudden downpours, and swings in humidity, so picking the right material from the start makes all the difference. The first year after a fence is installed reveals a lot. Finishes fade, boards shift, and posts settle. Joints also show if the materials can handle Pasadena’s heat, humidity, and rain. Last summer, a family swapped their sagging wood fence for budget vinyl. By spring, the sun-facing panels had yellowed. A corner also loosened during storms. Their neighbor’s sealed cedar stayed bright; however, it needed a fresh coat after the rainy season. This guide compares wood, vinyl, and chain link using first-year lessons. It highlights durability, upkeep, and total cost for superior fence installs in Pasadena. This way, readers can spot trade-offs and make confident choices.

Why Fence Materials Matter in Pasadena?

The National Weather Service (NWS) says that summers here often reach the upper 80s °F. They bring thunderstorms and high humidity. In contrast, winter nights can drop close to freezing. These conditions can cause UV damage, keep surfaces wet, and make parts expand and contract. Most homeowners hire contractors. They do this because it takes skill to turn climate data and standards into the right post sizes, embedment depths, finishes, and care plans. For example, wind checks for fences often follow methods in the American Society of Civil Engineers Standard 7.

Overview of Humid Subtropical Climate and Environmental Challenges

Local forecasts explain that warm seasons bring high humidity and frequent thunderstorms, which can leave surfaces damp longer and speed up wear. In winter, nights near freezing can lead to daytime thaws. This allows joints and coatings to flex with changes in temperature. Some storms bring strong gusts that challenge posts, even when average winds are mild, according to NWS. According to the USDA Forest Products Laboratory, exterior materials exposed to sunlight degrade over time under the combined stressors of UV radiation, moisture cycling (wetting and drying), and temperature fluctuations.

Material 1: Wood Fences — Performance, Pros, and Cons

Outdoor wood without steady finish protection can change color, crack at the surface, and face a higher decay risk. The USDA Forest Products Laboratory and the USDA Wood Handbook explain that the solution is steady yet straightforward: use the right preservatives and finishes, and maintain them regularly. Some species, such as certain cedars, naturally resist rot to a certain extent; still, long life depends on proper drainage details, regular finish care, and keeping wood off the ground. Corrosion‑resistant fasteners and a small gap above grade help the lower edges dry out faster. In humid summers like Pasadena’s, choosing a finish designed for sun and moisture exposure can help wood look better, last longer, and require fewer touch-ups.

Material 2: Vinyl Fences — Durability and Maintenance

The standard for rigid poly (vinyl chloride) (PVC) fence parts outdoors is ASTM F964. Asking for products that meet this standard supports claims about durability and stable size outside. PVC expands and contracts slightly with heat, so installers leave room to adjust and set posts correctly to minimize stress. Simple washing keeps the surface clean. Many Creekstone Pasadena homeowners look for UV-resistant vinyl options. One quick check is to ask whether the product meets the weatherability requirements of ASTM F964. Thicker profiles and reinforced rails can help with bumps and hits. Most wind design, though, is handled separately with methods that usually align with ASCE 7.

Material 3: Chain Link Fences — Strength and Limitations

ASTM A392 sets the zinc‑coating rules for galvanized chain link fabric. Heavier zinc coatings and compatible galvanized or polymer‑coated frames tend to last longer in wet, humid places. The Department of Defense’s corrosion guidance also notes that tougher environments call for stronger coatings if you want a longer service life. For open yards or corner lots—especially along streets like Twilight Way and Evening Star Dr—many contractors select “wind‑rated” posts by applying wind methods aligned with ASCE 7 and using fence wind load guides, ensuring the post size and embedment match the site.

How to Choose the Best Fence Material for Your Pasadena Home

Think about exposure first. Full-sun yards benefit from UV-resistant finishes or materials. Low spots or areas with slow drainage need designs that limit how long water sits on posts and boards. Those are basic durability habits from the USDA Wood Handbook and the Forest Products Laboratory. For wind and impact, pros usually use methods aligned with ASCE 7 and fence wind guides to size posts and set embedment based on the site, height, and how solid or open the wall is. For logistics, if a property is near a busy location, such as Pasadena Crossroads, it helps. Planning deliveries during off-peak hours helps the concrete cure properly. This also makes the site safer..Creekstone and nearby neighborhoods prefer low-maintenance fences. Asking about standards, coatings, and care tips can help.

What Factors Affect Fence Durability in the Mid-Atlantic Climate

Three things matter most. UV can break down finishes and some polymers; moisture cycling raises decay and corrosion risk; and heat and cold make joints and fasteners move. The USDA Forest Products Laboratory addresses UV and moisture issues. Meanwhile, defense-sector corrosion resources show how coatings reduce rust in harsh conditions. Helpful steps include making sure posts drain, keeping wood off soil, and letting PVC move as it heats up. These match USDA guidance and the scope of ASTM F964.

Why Maintenance Practices Differ by Fence Material in Pasadena

How long a wood finish lasts depends on the finish type, surface prep, and exposure, says the USDA Forest Products Laboratory. A practical plan is to inspect each year and refinish based on what the product calls for and what the surface shows. For PVC, most care is simple cleaning and a quick check that rails are supported and can move as designed. For chain link, touching up any scratched coating quickly helps slow rust. These are the same habits reflected in ASTM F964 for PVC and in standard corrosion‑control practices. In Creekstone Pasadena, a simple yearly walk‑through after the wet season—checking finish wear on wood and rinsing pollen or mildew from vinyl—can catch minor issues early and keep maintenance light.

Side-by-Side Look: Which Fence Wins?

Here’s how each choice typically performs in terms of upkeep and appearance, which are key factors in improving curb appeal and home value in Pasadena through fencing.

- Wood: Usually needs more care than plastics and coated metals. Results depend on the species, detailing, and steady refinishing under UV and moisture conditions. The USDA Wood Handbook and the Forest Products Laboratory both emphasize these basics.

- Vinyl (PVC): Products that meet ASTM F964 are tested for UV and weathering performance. Plan for some heat movement and keep cleaning simple.

- Chain link: Fabric that meets ASTM A392 and frames with coatings chosen for tougher, wetter conditions can last longer and need less upkeep.

| Priority | Good | Better | Best |

| Low maintenance | Chain link with galvanized fabric and upgraded coatings | Vinyl (PVC) that meets ASTM F964, simple cleaning | Vinyl (PVC) meeting ASTM F964 with thicker profiles and reinforced rails |

| Privacy & looks | Chain link with slats or hedging | Rot‑resistant wood detailed for drainage and kept off the soil | Well‑finished wood with steady refinishing for the highest curb appeal |

| Budget friendly | Chain link with ASTM A392 fabric | Basic vinyl (PVC) meeting ASTM F964 | Optimized mix: vinyl for privacy runs, chain link for utility perimeters |

| Weather resilience (sun, humidity, storms) | Chain link with upgraded frameworks for wet conditions | Vinyl (PVC) meeting ASTM F964; allows for heat movement | Any material with posts sized/embedded using ASCE 7‑aligned methods for wind-exposed sites |

Frequently Asked Questions

What type of fence lasts the longest with minimal maintenance in Pasadena?

Systems with precise material specifications—such as PVC that meets ASTM F964 and galvanized fabric per ASTM A392—often require less maintenance than unfinished wood. This is especially true in humid, sunny settings. When paired with properly sized frames, they perform well. Site conditions still matter most.

How often should a wood fence be sealed in humid summers?

The Forest Products Laboratory states that coating life depends on the finish type, preparation, and exposure. Many contractors suggest checking yearly and refinishing based on the product and what you see on the surface.

Will vinyl fade in the intense sun?

ASTM F964 checks weatherability and color retention. Request compliance paperwork and read warranty terms to set clear expectations.

Can chain links resist rust in wet seasons?

Yes, when galvanized fabric meets ASTM A392, and frames use upgraded coatings. Touch up scratches quickly to slow the spread of damage.

Do freeze‑thaw cycles damage fences here?

Moisture at post bases and in the ground can make freeze‑thaw worse. Good drainage, keeping wood off soil, and allowing PVC to move are simple ways to reduce risk.

Build It Right, Right Now

Get a fence that looks great and holds up to Pasadena weather, installed by a local team that stands behind the work. All Around Fence and Decks, LLC has served Maryland homeowners for 25+ years with fast scheduling, clear communication, and reliable craftsmanship. Ready for a tailored plan for your yard, timeline, and budget? Contact: (443) 838-9374 – 8130 Ventnor Road, Pasadena, MD 21122 – www.allaroundfenceanddecks.com